Anticipate the obsolescence of your maintenance parts and avoid unexpected downtime

Obsolete maintenance parts can bring your operations to a halt. By identifying them in time, you can secure your equipment, reduce costs, and maintain productivity.

Why your maintenance parts become obsoletes?

End of production by the manufacturer

Manufacturers regularly discontinue parts associated with older technologies to focus on new product generations, making certain components unavailable.

Aging equipment

Industrial equipment is often used far beyond its originally intended lifespan. This leads to a decrease in the availability of necessary maintenance parts.

Supply chain pressures

Parts manufactured abroad or in limited quantities can become scarce due to logistical issues or supply disruptions.

Regulatory and environmental constraints

Environmental standards, such as RoHS or REACH, sometimes ban specific materials or components, rendering once-common parts obsolete.

The impact of obsolescence on your performance

Costly production downtime

When a critical part becomes unavailable, it can cause unplanned production line shutdowns. These interruptions lead to significant financial losses, especially in terms of productivity, delivery timelines, and customer satisfaction.

Resource immobilization

To mitigate obsolescence risk, some companies build up safety stocks, tying up capital and storage space. However, these parts are not always used, leading to increased costs without guaranteed return on investment.

Loss of competitiveness and responsiveness

Struggling to quickly replace obsolete components slows down the ability to respond to demand shifts or unexpected failures. This impacts operational flexibility, innovation, and ultimately the company’s market position.

Anticipate obsolescence with the kheoos solution

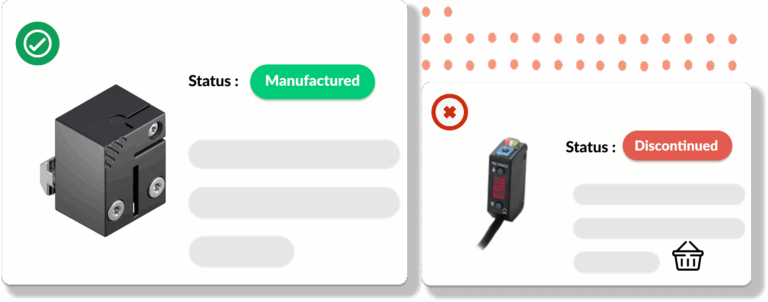

Step 1 – Identify parts at risk of obsolescence

Through intelligent analysis of your inventory data, our solution automatically detects items exposed to obsolescence risk. By cross-referencing your data with our enriched database of over 85 million parts, we highlight components that have been discontinued by the manufacturer.

Our artificial intelligence relies on original bills of materials to provide a reliable and prioritized diagnosis.

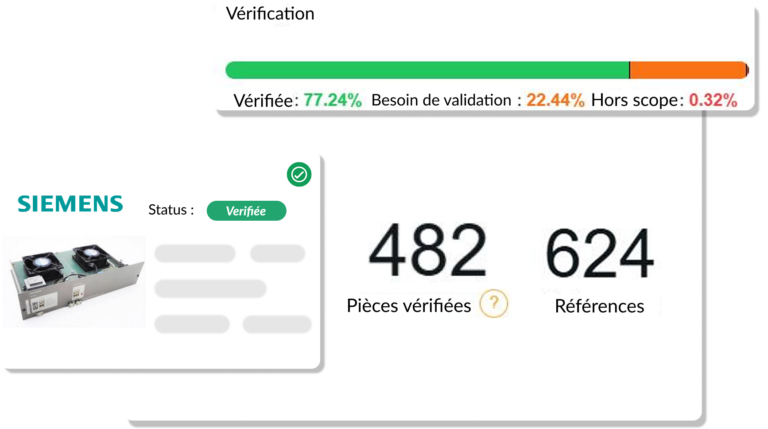

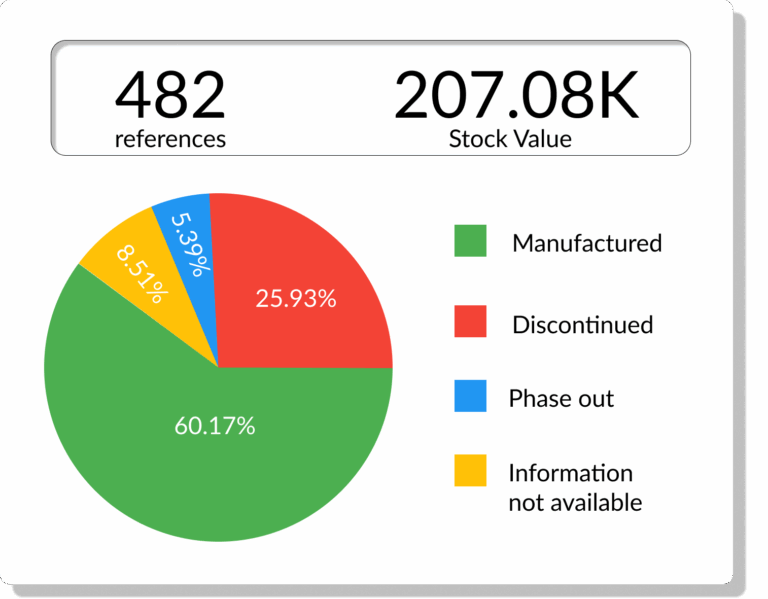

Step 2 – Analyze and manage your risks

Once obsolete or soon-to-be-obsolete parts are identified, mykheoos provides you with a consolidated, actionable view. Each part is documented with a clear status: active, phasing out, discontinued, or information unavailable.

You gain access to an interactive dashboard to support decision-making and anticipate potential impacts on your production lines or maintenance operations.

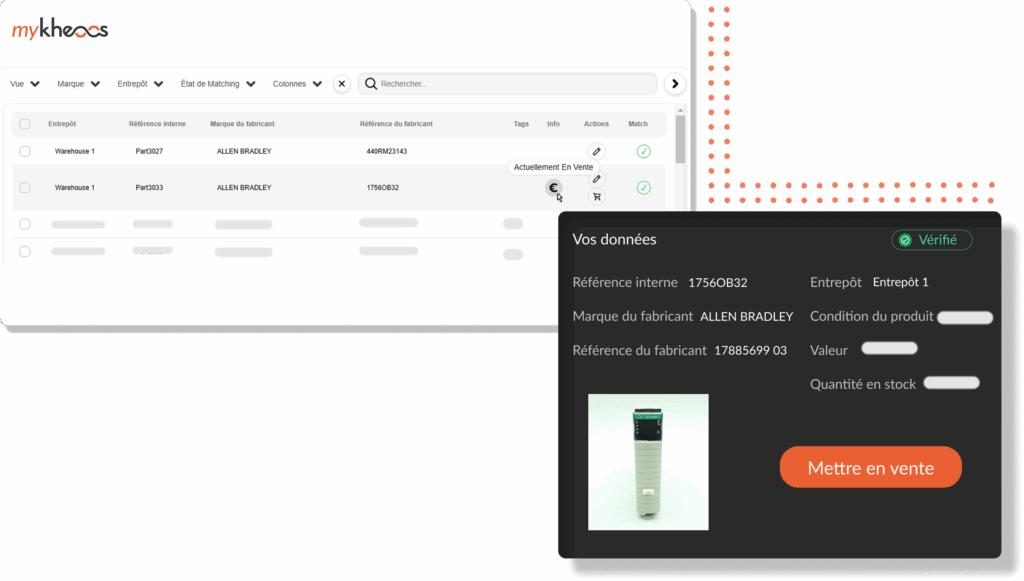

Step 3 – Give value back to your obsolete parts

Parts identified as obsolete shouldn’t become losses. We help you repurpose them through our industrial marketplace, kheoos market, which enables you to resell them to other manufacturers who still need them.

This approach is fully aligned with our circular economy mission: extending the life of industrial components, reducing waste, and turning dormant inventory into opportunities.

They say it best

Obsolescence threatens your production, it's time to take back control

Obsolete or soon-to-be-discontinued parts can cause critical shortages, line stoppages, and a loss of responsiveness in your operations. These hidden risks often lurk in poorly managed inventories or outdated databases. With our artificial intelligence technology, you can detect these threats early, secure your equipment, and anticipate your needs.

Prevent shortages, secure your processes, and unlock the value of your parts.