Visualize your common parts and optimize your spare parts management

Why is it so difficult to identify your common references?

Lack of coordination between sites

Each site manages its own inventory, often with different tools or standards, making consolidation complex or even impossible.

No unified codification

Identical parts may be named differently from one site to another, making automatic detection difficult and skewing analysis.

Heterogeneous or incomplete databases

Incomplete inventories, unclear bills of materials, and vague descriptions make it hard to identify reliable matches.

Lack of cross-site visibility

Without a dedicated tool, it’s impossible to know in real time if a part available at one site exists elsewhere internally, even in urgent situations.

The impacts of lacking visibility on your common references

Uncontrolled overstock and duplicates

Without a consolidated view, identical parts may be ordered multiple times by different sites. The result: excessive, unevenly distributed stock that’s costly to manage.

Avoidable shortages

A part might be missing at one site while sitting unused at another. Lack of visibility prevents fast response and limits internal transfer optimization.

Loss of efficiency and synergies

The absence of shared data slows down bulk purchasing, collaboration between entities, and reference standardization, ultimately harming overall performance.

Optimize the management of your common references with the kheoos solution

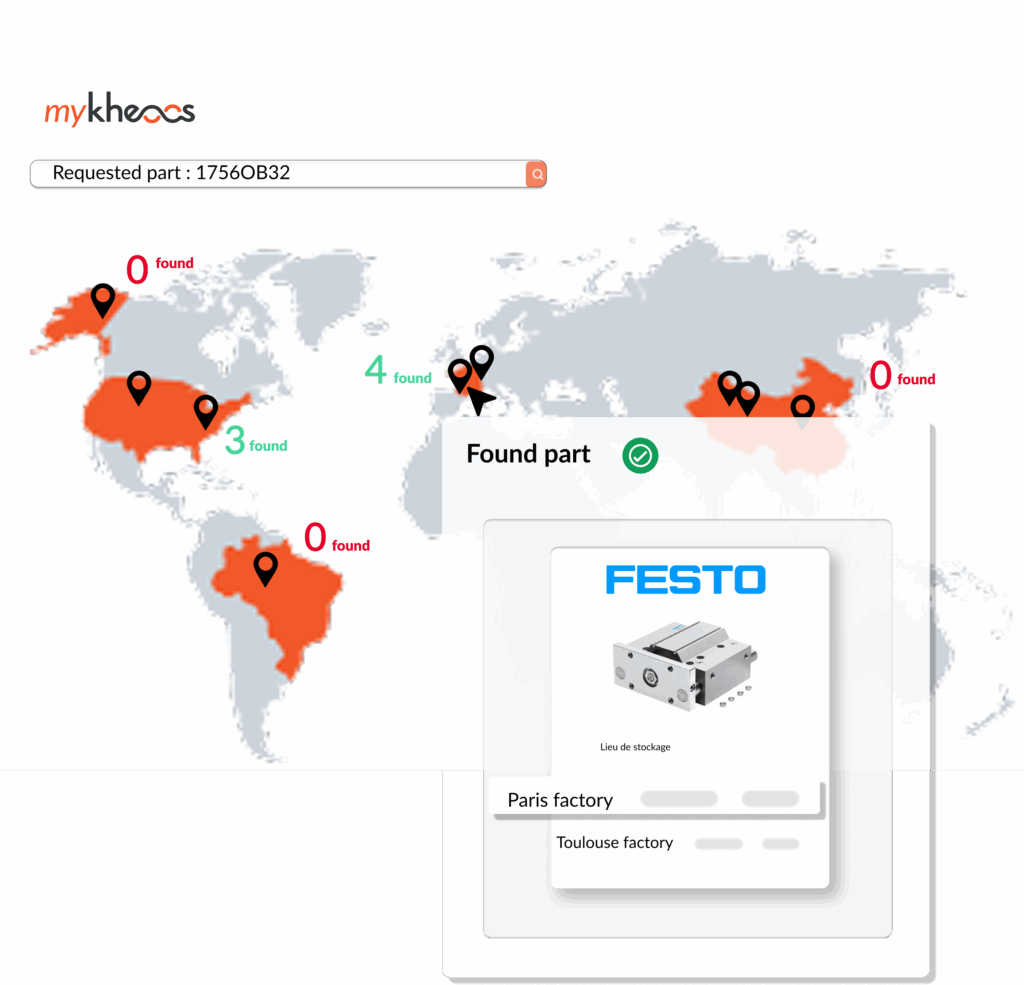

Step 1 – Identify your shared references

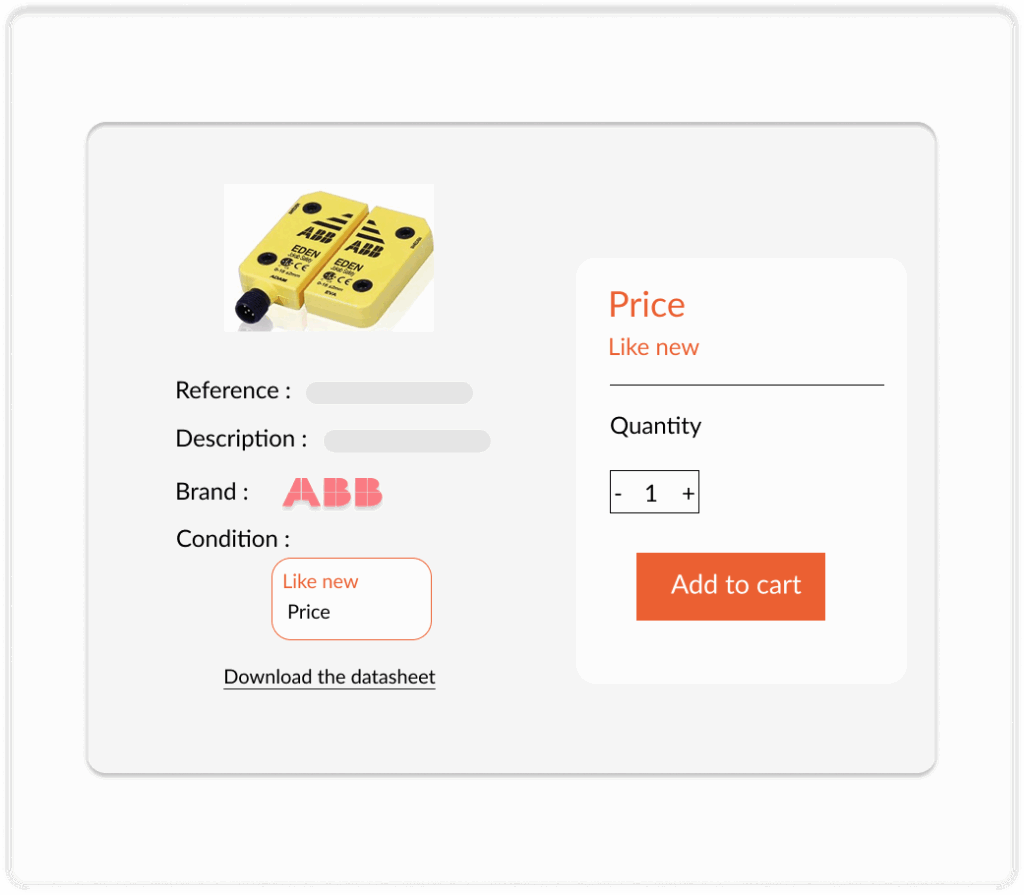

Our solution analyzes your inventories and detects parts that are present across multiple sites. By cross-referencing your data with our enriched database of over 85 million references, we highlight common references that are:

Shared between different sites or departments

Overstocked at one site but missing at another

Suitable for pooling or transfer to optimize resource management

With kheoos’ artificial intelligence, your inventories are consolidated in real time, making it easier to visualize shared parts and enabling optimal management.

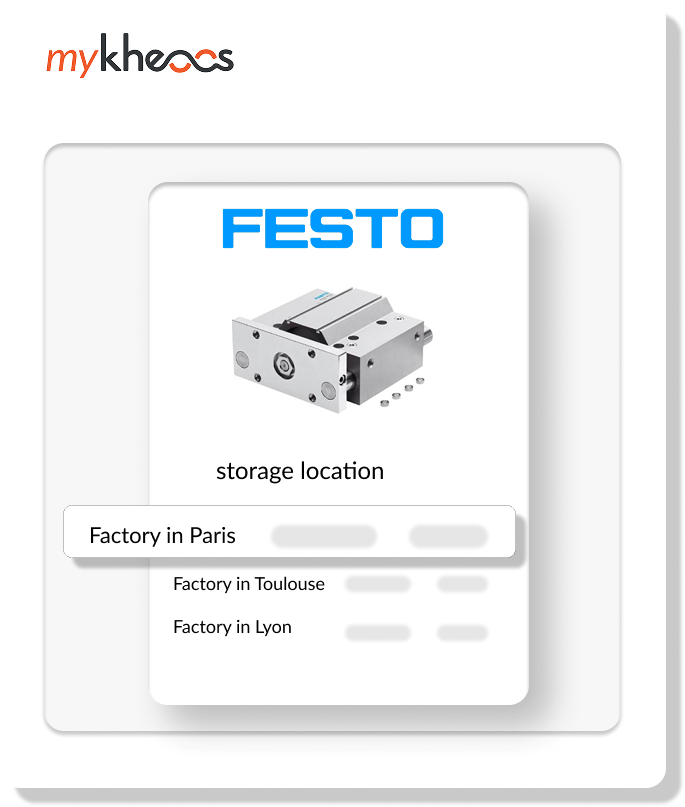

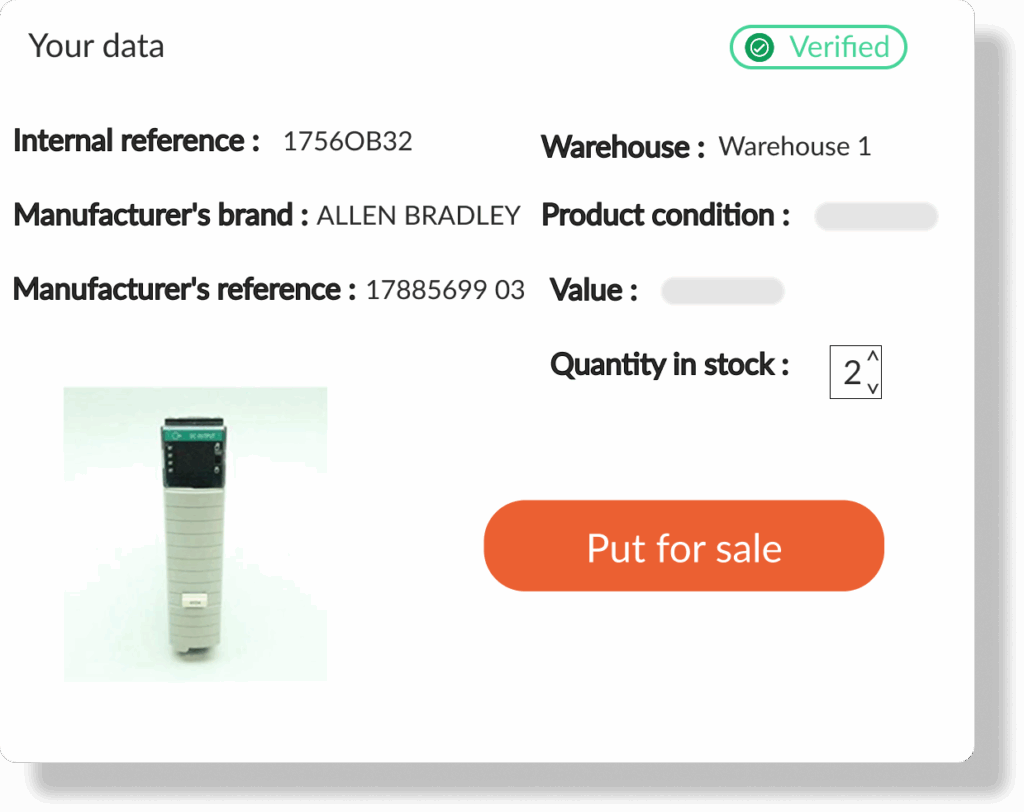

Step 2 – Centralize and optimize your data

Once common references are identified, kheoos provides you with a consolidated and clear view, where each part is documented with the available quantity at each site.

With this global overview, you can easily check stock availability at other production sites before making a new purchase, helping you avoid unnecessary expenses.

Step 3 – Facilitate sharing and pooling

Shared parts shouldn’t become a bottleneck. With kheoos, we help you promote stock pooling between sites and departments. You can:

Transfer parts between sites based on needs

Pool recurring part orders to negotiate better rates with suppliers

Reduce procurement costs while increasing efficiency

This collaborative and strategic approach not only helps you manage your inventory better but also secures more favorable purchasing conditions.

The management of your common references impacts your performance, it’s time to take control

Poorly managed inventory, unidentified duplicates, or avoidable shortages can lead to production delays, unnecessary costs, and inefficient resource management. These risks often remain hidden in scattered or unsynchronized inventories. With our advanced technology, you centralize your data, optimize your resources, and improve coordination across your sites.

Optimize your inventory, reduce procurement costs, and increase responsiveness.

They say it best